3D Print Metal from CAD Product Design

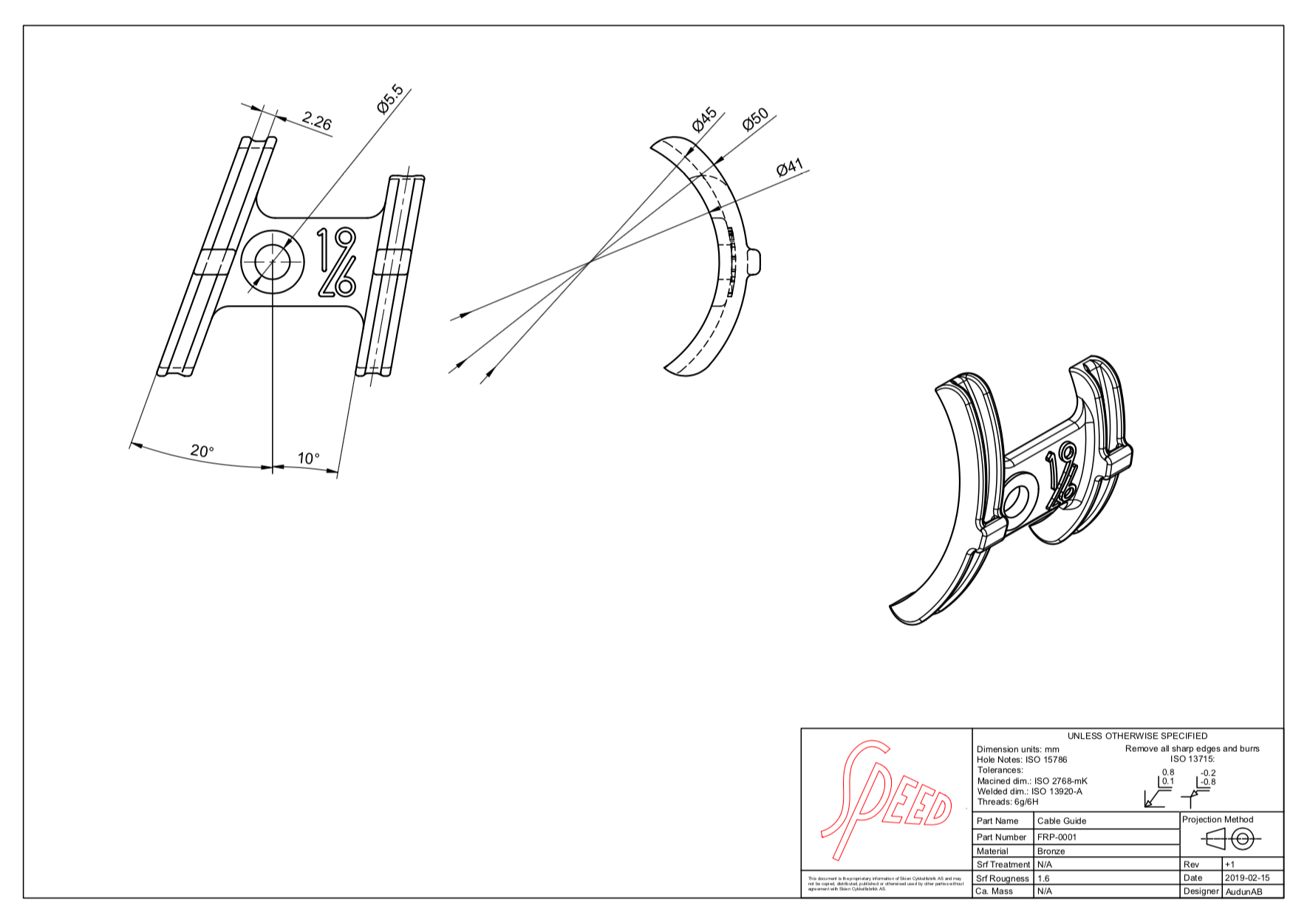

Bicycle parts can be a piece of jewelry. When we did the product design of the bottom bracket cable guide for Skiens Cykkelfabrik we aimed high. Using cast molding and 3D printing we designed and manufactured a beautiful bicycle component in bronze. The result is stunning - in our opinion.

From 3D Printed Plastic to Metal

3D Printing has been available for a while. Currently the FDM type printer with PVA material would be the fastest, cheapest and easiest way to prototype products. Prototyping is a fun lo-fi stage, where you can iterate quickly with cheap plastic pieces.

If the project develops as you had predicted and the designed part is successful and needed, you might need to take that piece to the next level. In some cases this would mean creating the first CNC machined prototype. But some geometries (especially when designed for 3D-printing) can be very difficult, time consuming and expensive to machine. And maybe you have some variations you would like to try, and that would multiply those problems.

This is where metal 3D printing comes in. With 3D printing there is low set-up cost and little extra to test different variations. Several different techniques can create different results and almost any solution is possible. Especially interesting for us was the lost wax cast molding technique. Where a design is 3D printed in wax. The wax model is placed in mold sand and burned away at high temperature. This creates a cavity where molten metal is poured which creates a metal version of the wax design.

This is how we designed and manufactured the bronze bottom bracket cable guide for Skiens Cykkelfabrik.

Why Design a Custom Bottom Bracket in Bronze?

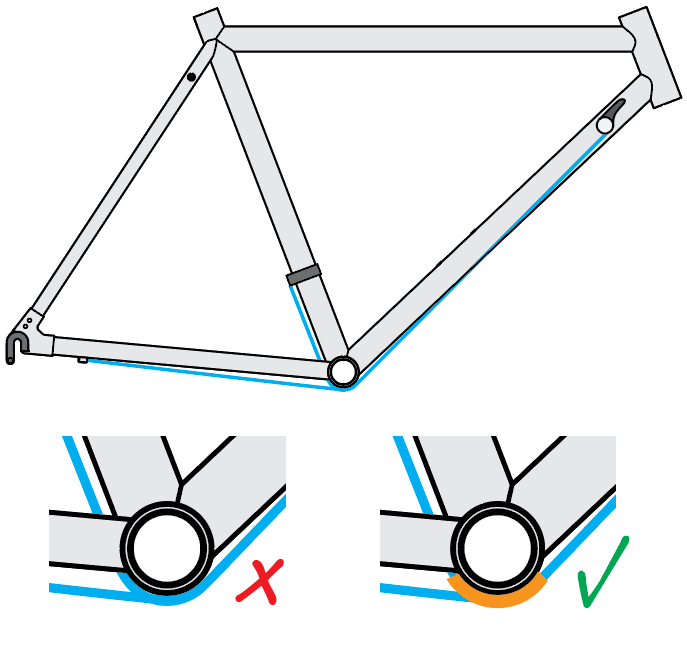

A bottom bracket cable guide is a piece that sits under the bottom bracket. It keeps the gearing wires in place and allows them to slide easily. All wear is done to this replaceable piece, so when it is worn out you can simply get a new one.

These pieces are usually around 1USD and in plastic. For Skiens Cykkelfabrik we wanted to create something unique, exclusive and a conversation piece. So we decided to make this in bronze. Bronze makes sure this is self lubricating due to the tin content in the brass and will keep the friction low for many years to come.

Bicycle Component Jewelry - Just Because

If you want to start a conversation, just flip your classic road bike Speed TEN around, or just ride around, knowing that you have a piece of jewelry aiding your every shift. Just because...