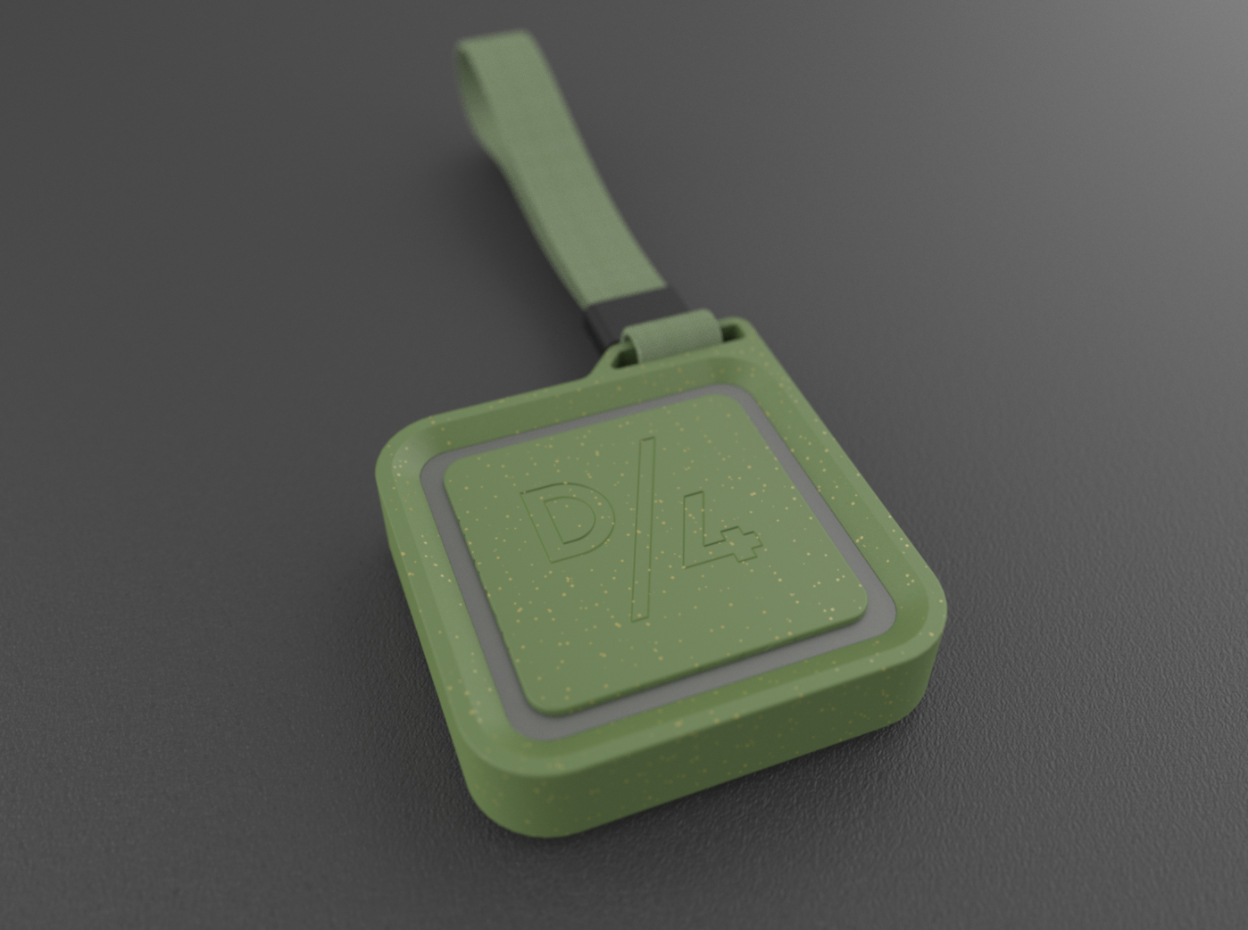

IOT Device Casing Design

The physical world can be harsh for an electronic device, and it also should be easy to use, place, and interact with. Any product should also represent their brands' styles and values.

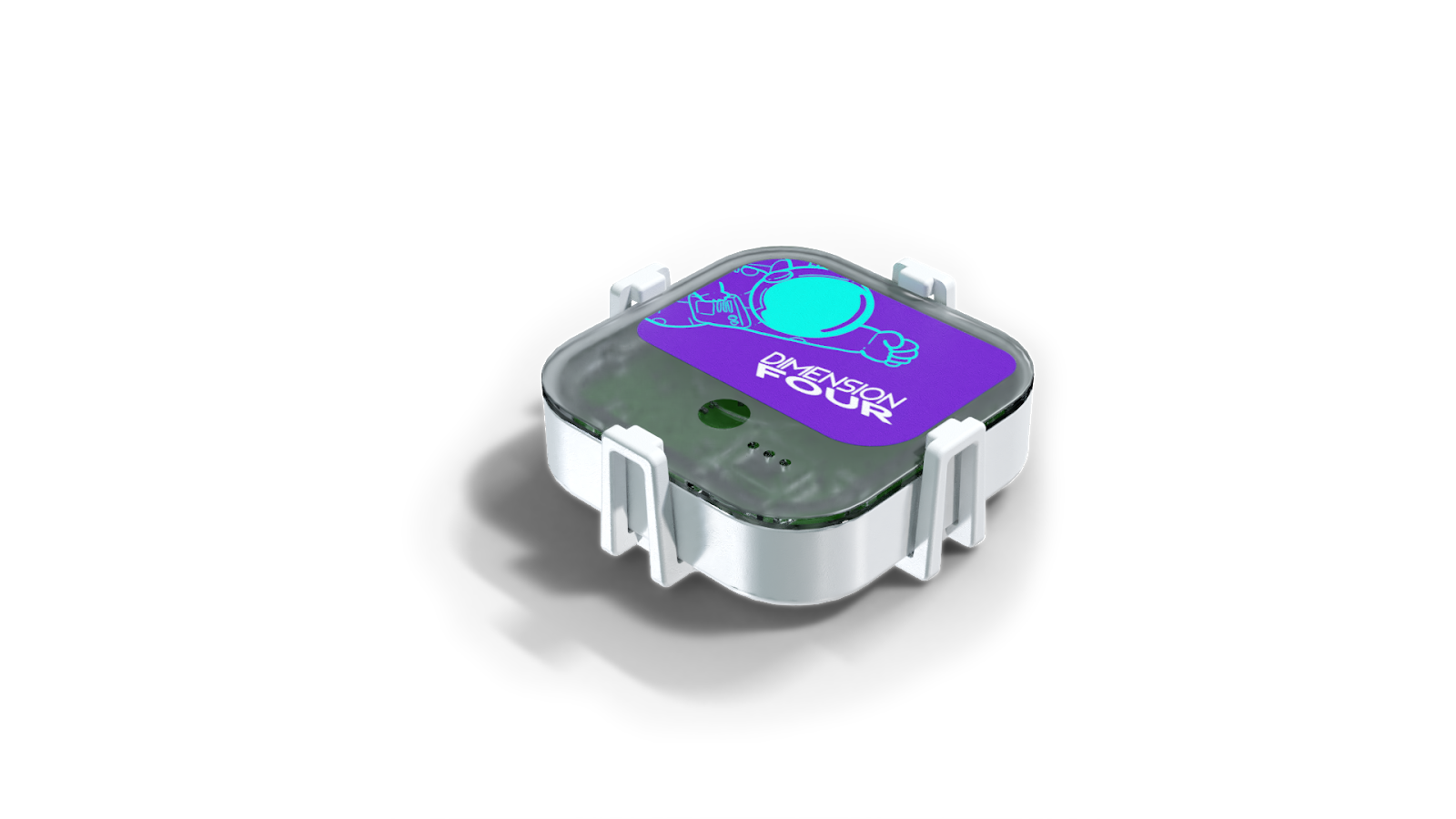

Our friends in Dimension Four have designed a performant, compact IoT PCB with a myriad of different sensors and asked if we could help dress it up.

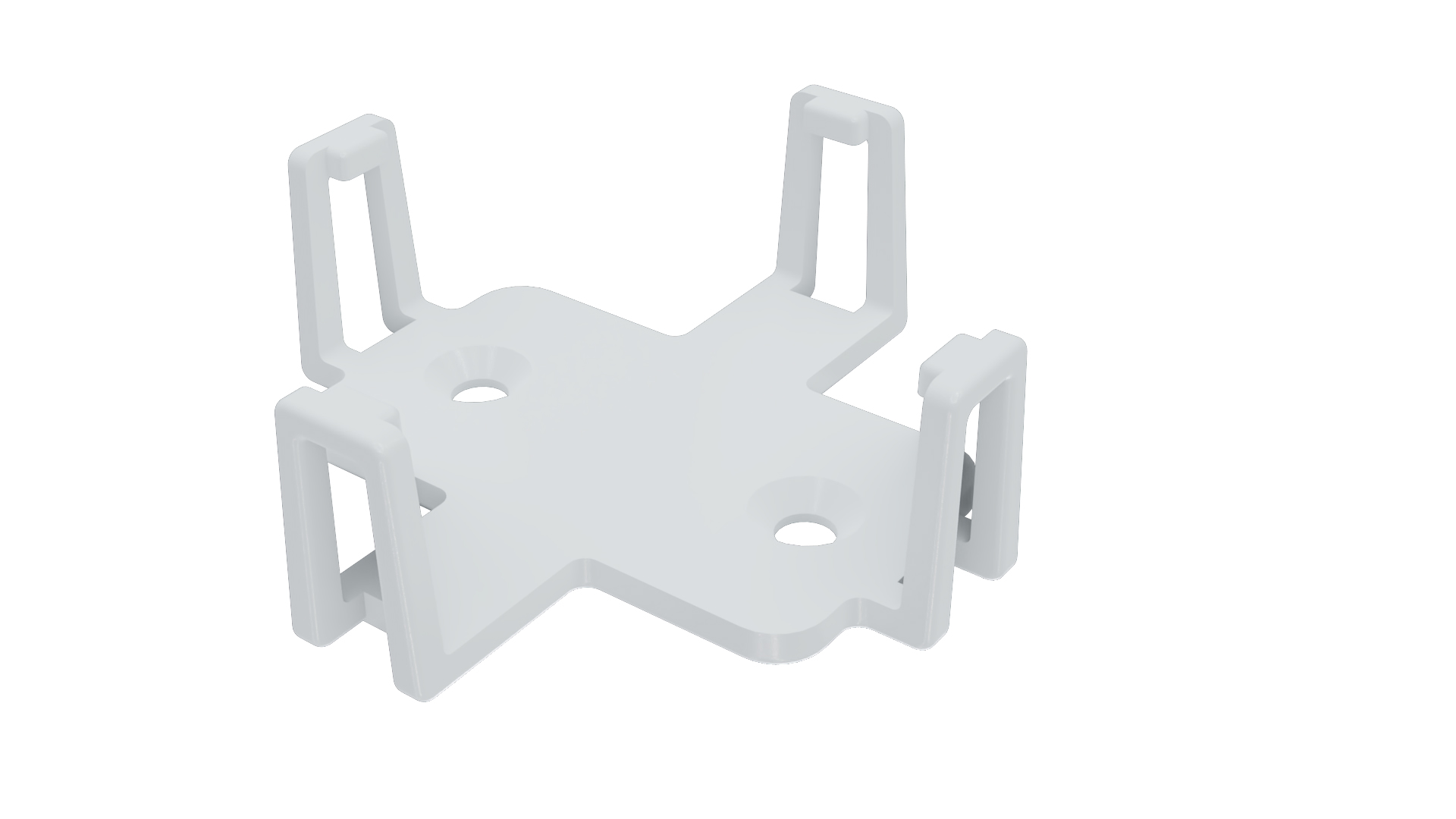

The starting point was this battery-run device that needed to be quickly and easily installed into a casing that could be waterproofed when needed but also allow the passing of air for a humidity sensor and pins for water detection.

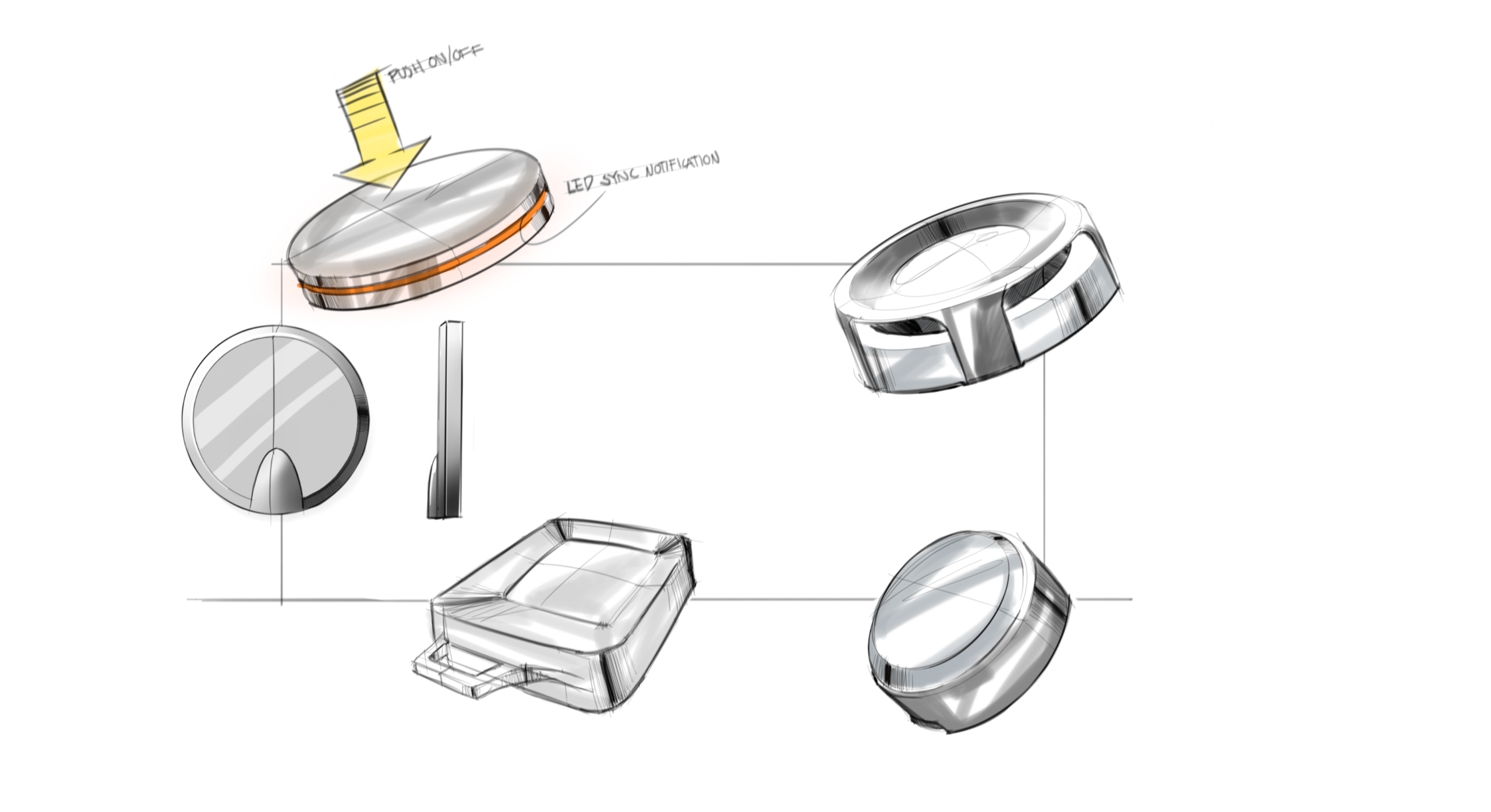

Sketches & Quick 3d-modeling

We started with some rough sketching to create ideas for the product design, and user experience. At the same time, we started looking into principles for manufacturing and assembly. Design for Manufacturing and Assembly is always on our list when doing development. Simply put, we need to make sure that the effort required for each extra assembly step or is worth the effort.

Rapid prototyping

During the process we do a lot of rapid prototyping, both digitally and physically. The fastest iterations we print inhouse, so we can do many per day. For protoypes in very exotic materials or high precision, we order them in from one of our suppliers.

Design & Engineering

In this case we designed for efficient production and manufacure of high volumes, and ended up with injection molding as the best alternative. We designed and engineered the parts to be suitable for injection molding, with all required features and geometry. We sourced a suitable supplier and assisted through the entire ordering process until the product was delivered.

Having both design, engineering and other needed resources inhouse, really helped speed the process up.

Animations & Illustrations

Illustrations and animations communicate very efficiently. We utilized both to speed up and help communication with client, suppliers and marketing.

Details

Backside with label, water trap and water detection.

Result

Notice the polished area for the light sensor and the air vent holes that can be sealed with a membrane, to be waterproof but damp open to allow humidity sensing. Using labels instead of embossing into the parts, also made the product more flexible regarding brand changes.