Product Design: from Idea to Production Ready Bicycle

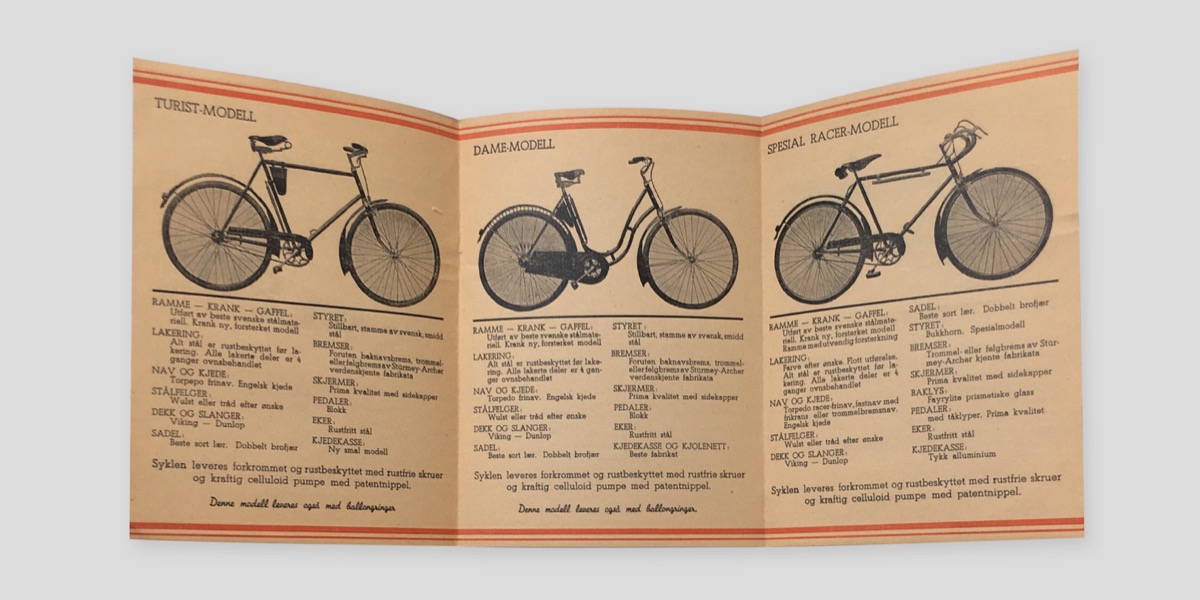

Skiens Cykkelfabrik is an institution. Originally located in the same factory building as Snowball, the bicycle factory was founded in 1926 and produced bikes until 1961. The vision was to bring back the brand and design bikes with a timeless style and no-compromise quality. Snowball was tasked with product design for the single-speed bike Speed ONE, a re-launch edition city bike designed on the legacy from Skiens Cykkelfabrik.

Product Idea and Inspiration

The inspiration for the Speed ONE was found in the history books. We based the geometry and styling on models from the 1930s and 1940s. Our thought was: What if the first bikes from Skiens Cykkelfabrik were built today with the modern techniques and material that are available now?

In addition to taking the heritage from the first Speed bikes into consideration, we also defined guidelines including:

- Timeless design: minimalistic styling that is modern now and in 50 years from now

- Natural materials: aluminium, stainless steel, leather and cork

- No plastic: there are no plastic components on the bike

- No compromise on quality: the bike is designed to last for the next generation

With this minimalistic approach, we also decided that this first bicycle from Skiens Cykkelfabrik should be named Speed ONE. The name reflects that it is the first bike from the re-launch of the company. It is also a single speed bike.

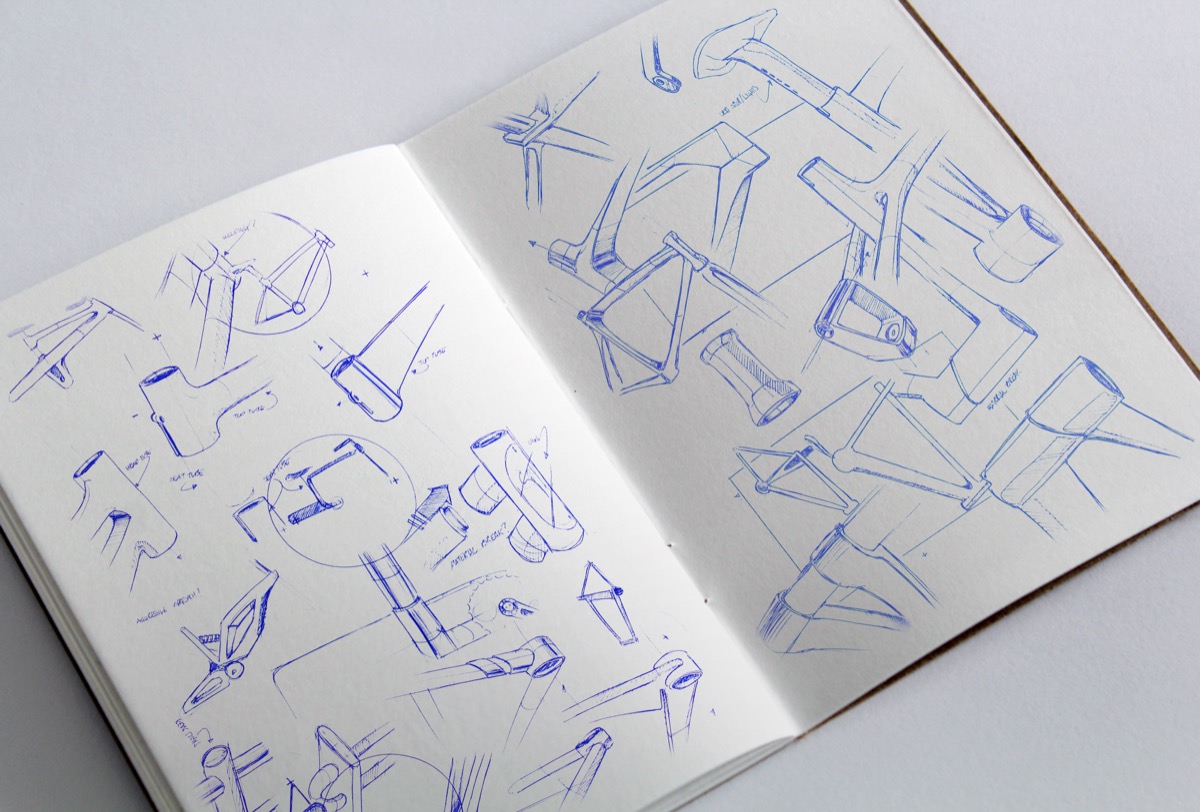

Product Concept Sketches

The product design process at Snowball started with visualization via sketches. This usually includes simple ball-pen sketches to quickly visualize the direction and style language. Such a process quickly helps us define the direction and align the vision for the project.

The Snowball Lounge Chair Concept is another example of product design.

Bicycle 3D CAD Design

3D CAD design is central when designing a product. In the CAD process, we can quickly iterate and change components in a visual way. This is where we can verify details like clearance and fit. We can combine oem parts like brakes and stem with our custom-designed parts like frame, crank, grips and so on. Make sure it all fits and can be produced. Neat!

3D Rendering & Visualization

Ultimately, our goal is to design products that are desirable. With high quality 3D renderings of the product design, we can get a good idea of what the final product will look like. And let's face it, it is a lot quicker to iterate in CAD than physical prototyping.

Parts are designed in detail and prepared for CNC production.

Details matter

Product design is all in the details. Why? Because details matter. A product like a bicycle is relatively simple, making the details matter even more. The product is in its details. For the Speed ONE, we pulled out all the stops and custom-designed almost every single component including custom:

- hand welded aluminum frame

- leather city saddle

- leather handlebar grips with custom engraving

- custom aluminium crank and chainring

- 700c white tires

- wheel hubs

Finally a Production-Ready Bicycle

The final part of the design process is physical prototyping. This is where we weld up custom frame and assemble all custom and stock components. The final prototype is test ridden and quality controlled. The Speed ONE was tested by the worlds best Norwegian trials rider Eirik Ulltang.

The final Speed ONE product is nothing less than a luxury bicycle. Check out all the details of the Speed ONE Launch Edition. It is produced in only 91 numbered bikes.

Once the Speed ONE was ready for production we started the product marketing and growth marketing. Starting with storing the product information in a headless PIM so customers can buy the Speed ONE online.